Injection molding » Flexistrong Plus – Injection Molding

Flexistrong Plus®

High-performance polymer of the PVDF group

Description

Flexistrong Plus® is a highly crystalline, thermoplastic resin with good mechanical and thermal properties and excellent chemical resistance. It is suitable for splints, model casting, telescopic dentures and implant technology, among other applications. The Flexistrong Plus® Disc is currently available in the colors A2; A3.5; pink, pink opal and natural.

Application area

- Crown and bridge technique

- Model casting / clamping technique

- Splint technology

- Full anatomical long-term temporaries

- Scaffolding technology

- Total / partial prosthesis

Advantages

- Extreme fracture stability

- Plaque resistant

- High transulgence

- Can be veneered

- High chemical bonding to other resins possible

Technical data

| Module: | 2000 MPa |

| Flexural strength: | 90 MPa |

| Ball indentation hardness/Rockwell | 80 MPa |

| Temperature of dimensional stability | 145°C |

| Water absorption | <0,04% |

* The technical/physical values given are measurement results from institutes and may be subject to fluctuation.

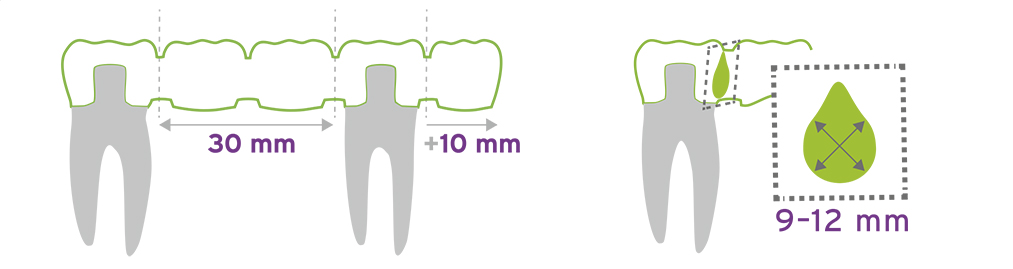

Processing data injection molding

| Cartridge preheating | 15 Min. |

| Spray temperature | 220°C |

| Spray pressure | 6 – 7 bar |

| After pressure | 1 Min. |

Biocompatibility

Flexistrong Plus® is characterized by the highest biocompatibility and is suitable for allergy sufferers.

Injection molding colors

A2 • A3,5 • rosa, rosa opal • natur

Things to know

Very high esthetic translucency. Plaque resistance very dependent on patient care.

Extreme fracture stability, high toughness, extremely low water absorption characterize this high-performance resin.

Almost unbreakable, can be destroyed by improper handling.

Working instructions

Flexistrong Plus®

More application examples